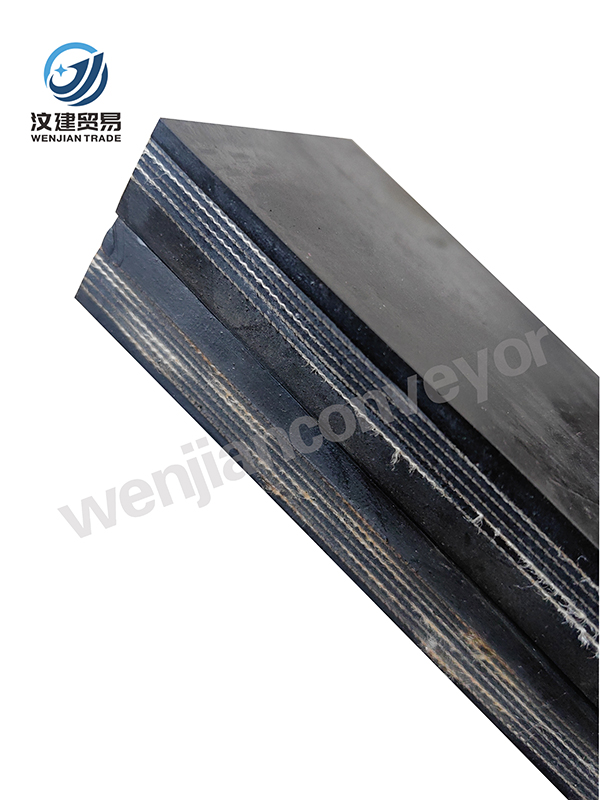

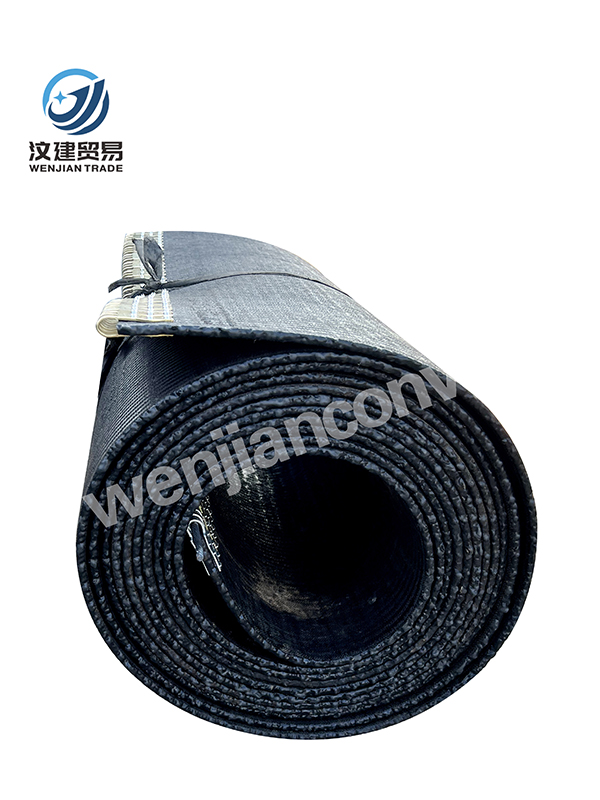

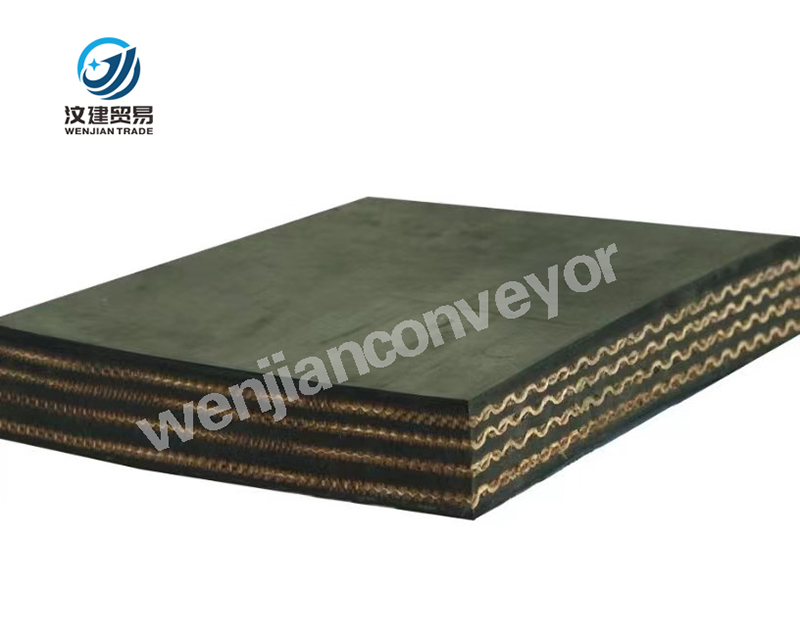

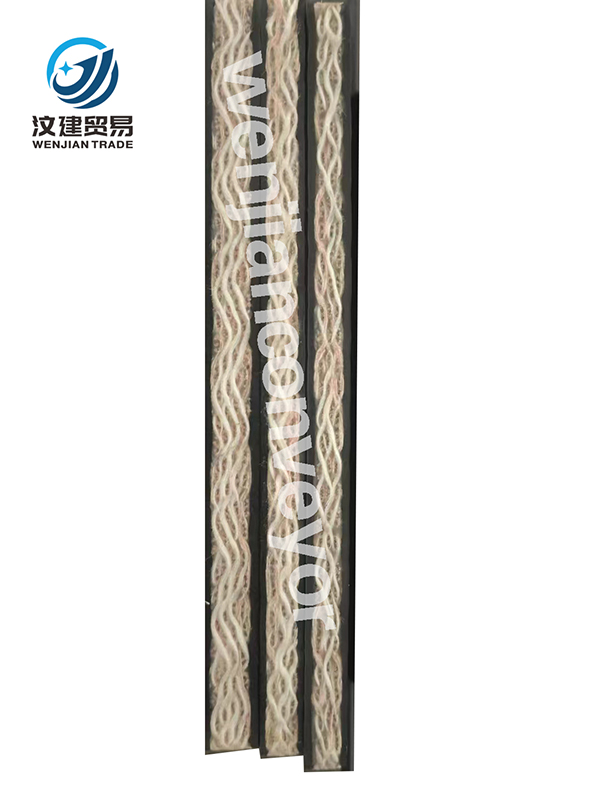

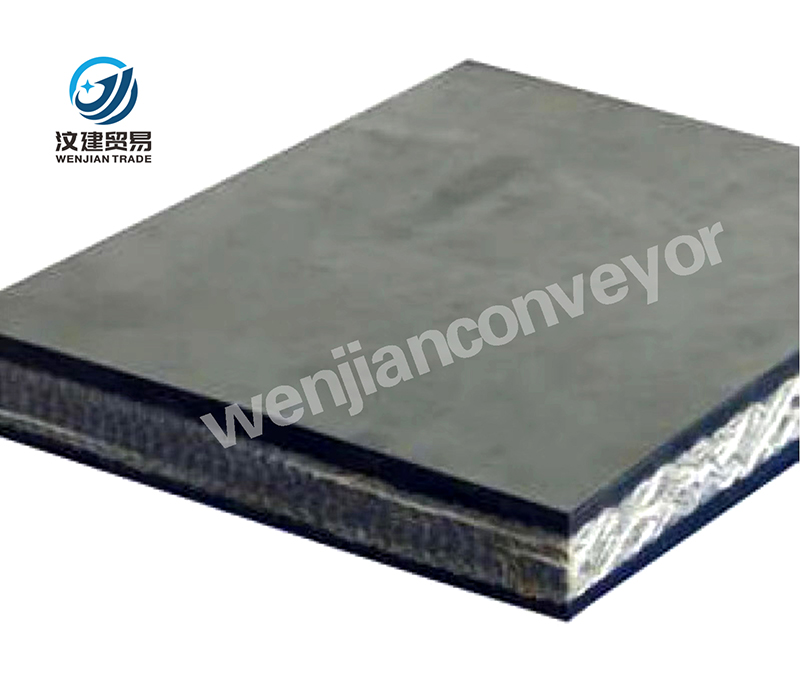

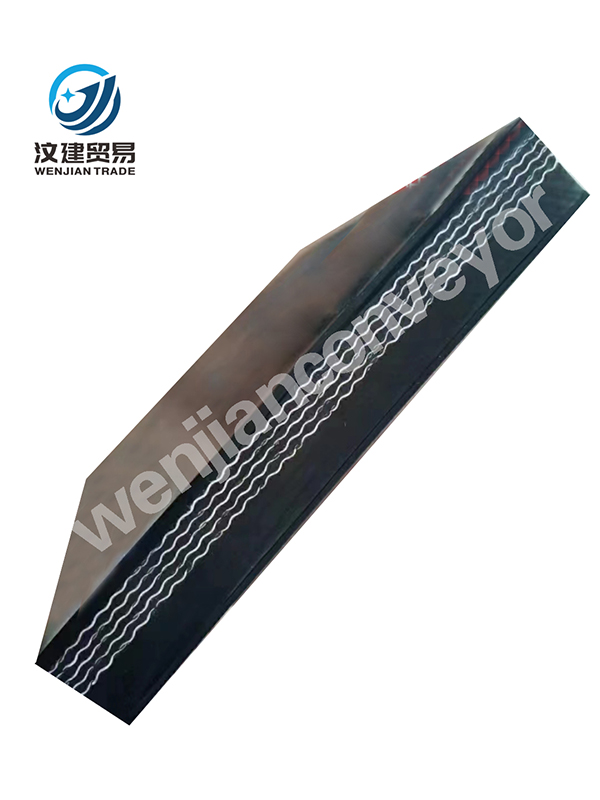

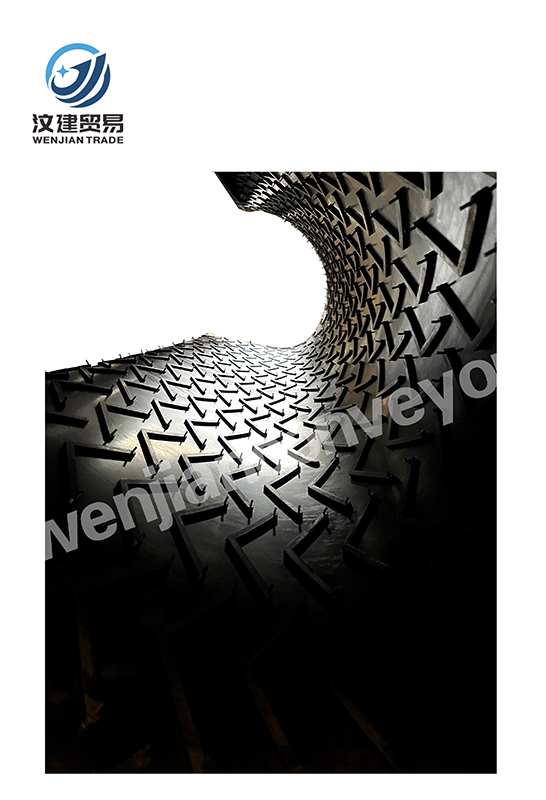

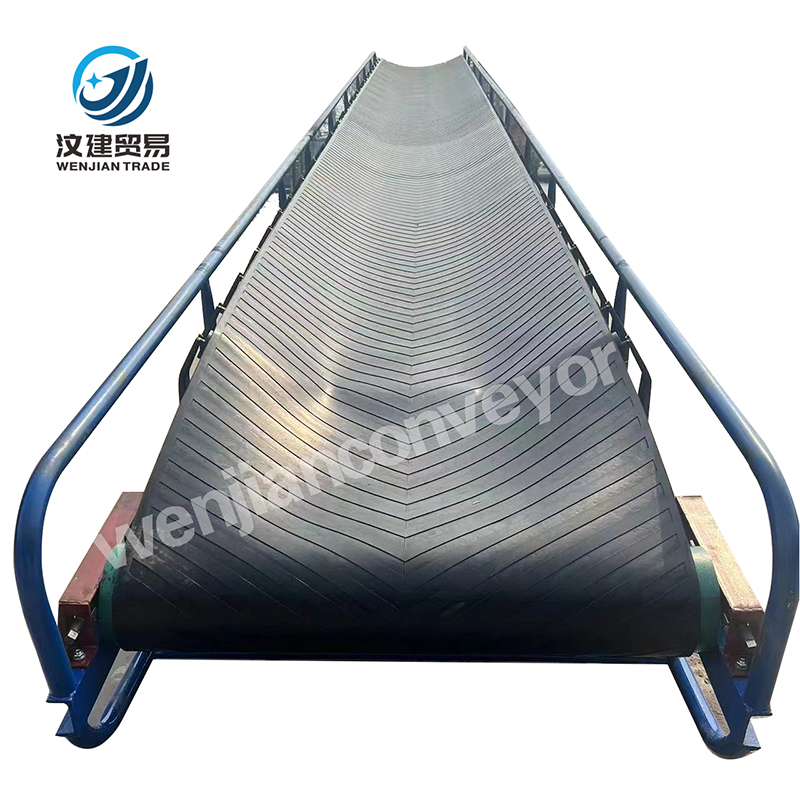

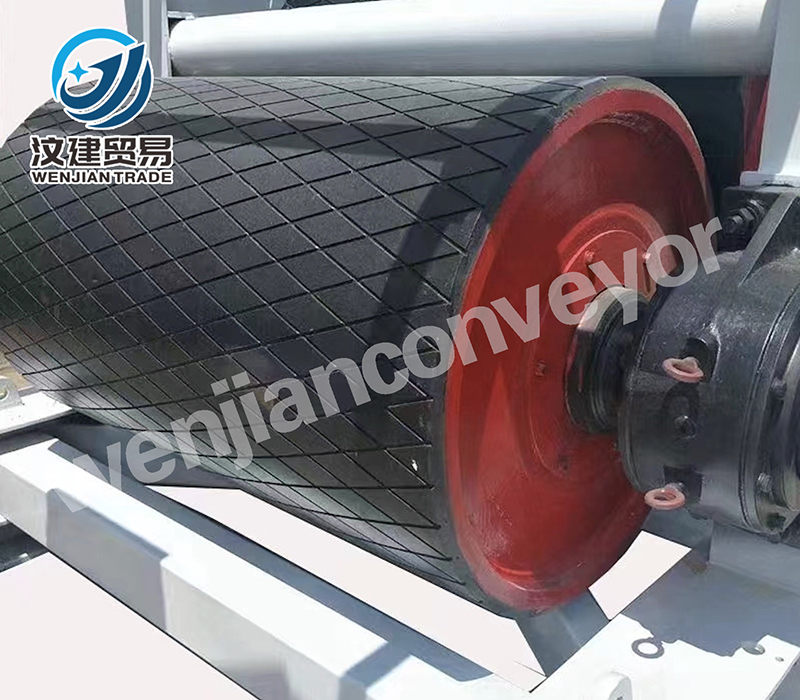

Highly wear-resistant conveyor belts generally have a nylon cloth layer inside and a rubber covering layer outside. The inner nylon cloth layer provides tensile force, and the outer rubber is specially treated to have ultra-high wear resistance, which greatly reduces the wear rate of the conveyor belt caused by minerals and increases the use time.

| Parameters of High Wear-resistant Conveyor Belt | |||||||

| Type of Fabric | Fabric Model | Single Stretch Strength | Canvas Layer | Lid Thickness(mm) | Belt Width(mm) | Conveyor Belt Type | |

| Top Cover | Lower Cover | ||||||

| EP Fabric | EP-100 | 100 | 2-8

Recommend not to be more than 6 layers |

2-25 | 0-15 | 500-2200 | Anti-impact type,

Wear resistance, Heat resistance, Flame retardant, etc. |

| EP-125 | 125 | ||||||

| EP-150 | 150 | ||||||

| EP-200 | 200 | ||||||

| EP-250 | 250 | ||||||

| EP-300 | 300 | ||||||

| EP-350 | 350 | ||||||

| EP-400 | 400 | ||||||

| EP-500 | 500 | ||||||

| EP-600 | 600 | ||||||

| NN Fabric | NN-100 | 100 | 2-10

Recommend not to be more than 8 layers |

2-25 | 0-15 | 500-2200 | |

| NN-125 | 125 | ||||||

| NN-150 | 150 | ||||||

| NN-200 | 200 | ||||||

| NN-250 | 250 | ||||||

| NN-300 | 300 | ||||||

| NN-400 | 400 | ||||||

| NN-500 | 500 | ||||||

| Cover Layer Performance | |||||||

| Performance | Tensile Strength/Mpa | Elongation at Break/% | Grinding Rate/mm3 | ||||

| H | 24 | 450 | 120 | ||||

| D | 18 | 400 | 100 | ||||

| M | 15 | 350 | 200 | ||||

| H:Used to transport sharply abrasive materials that have strong damage to the band;D:Used to transport high -wear materials;M:Used to convey moderate abrasion material | |||||||

WenJian

WenJian